+ Approved to ISO 9001:2008

+ Latest digital testing equipment including micron thickness, weight loss and admittance

+ Comprehensive process control

+ Full time solution analysis

+ Approved to ISO 14001

+ Winner of Groundwork Trust Award for waste effluent and water recycling

+ State of the Art water recycling/effluent plant

+ Continual monitoring of plant environmental impact

+ Advice on alloy section colours and finishes

+ Quotes in writing - typically the same day

+ Site visit if required - help us understand your requirements

+ Free sample colour swatch available. Call to request

+ Direct contact with senior staff

+ Delivery time to suit customer wherever possible

+ 4 process plants offer a full range of finishes and colours

+ Delivery by our vans or national carrier

Our success, to a large extent, is due to the dedication, quality and experience of our staff

Manchester

Colour Anodising's aim is always to exceed our customers' expectations

Manchester

We build a team around your needs and provide our clients with direct access to everyone.

Learn moreThe anodic oxide structure originates from the aluminium substrate and is composed entirely of aluminium oxide. This aluminium oxide is not applied to the surface like paint or plating, but is fully integrated with the underlying aluminium substrate, so it cannot chip or peel. It has a highly ordered, porous structure that allows for secondary processes such as colouring and sealing.

Anodising is accomplished by immersing the aluminium into an acid electrolyte solution and passing a current through the aluminium. A cathode is mounted to the inside of the anodising tank; the aluminium acts as an anode, so that oxygen ions are released from the electrolyte to combine with the aluminium atoms at the surface of the part being anodised. Anodising is, therefore, a matter of highly controlled oxidation - the enhancement of a naturally occurring phenomenon.

To see the range of standard colours we offer we have designed the colour swatchbook shown below. Click on the cover to see the range of colours. To see an individual colour click on the relevant blade which will reveal the colour name. Please call or email to order your free aluminium colour sampler which physically represents the colour swatchbook shown below.

For technical reasons connected with colour reproduction and media limitations, the colours shown may not be exact representations of the finished products.

The nominal thickness of coatings applied is 25-50 microns but a controlled thickness can be obtained from just a few microns up to 100 microns depending on the alloy chosen.

The wear characteristics of hard anodised aluminium are most favourable at low loads and compare most favourably with hard chromium and high speed steel, in most cases better.

The micro hardness of the coating varies significantly depending on the alloy chosen.

Generally the high strength alloys i.e. 2000 and 7000 alloys produce a micro hardness figure ranging from 250 to 350 micro Vickers and 6000 alloy range 400-500 micro Vickers.

A note of caution should be made when comparing micro hardness to wear resistance, the hardness measured by micron-indentation method does not represent the performance of the material.

It has been found that a hard anodised coating measuring 450mv will have a wear resistance of tool steel of 950 mv and even an anodic coating of highcopper alloy such as 2014 measuring 250-280 mv will often offer as much wear resistant as tool steels.

Hard anodic coatings have better abrasion resistance than conventional coatings of the same thickness. Corrosion resistance is further improved by sealing but with some loss in the abrasion resistance (about 20%).

Depending on alloy chosen and film thickness the colour varies from light grey to dark grey.

Due to the fact that the hard anodic film is an integral part of the aluminium, you will find that the adhesion properties are superior to that of any other coating applied to aluminium

Hard anodising will reduce fatigue strength considerably - up to 47%

Hard anodic coatings can withstand short exposures up to 2000°C. Long exposure to high temperature shows no adverse effect on performance, other than surface crazing

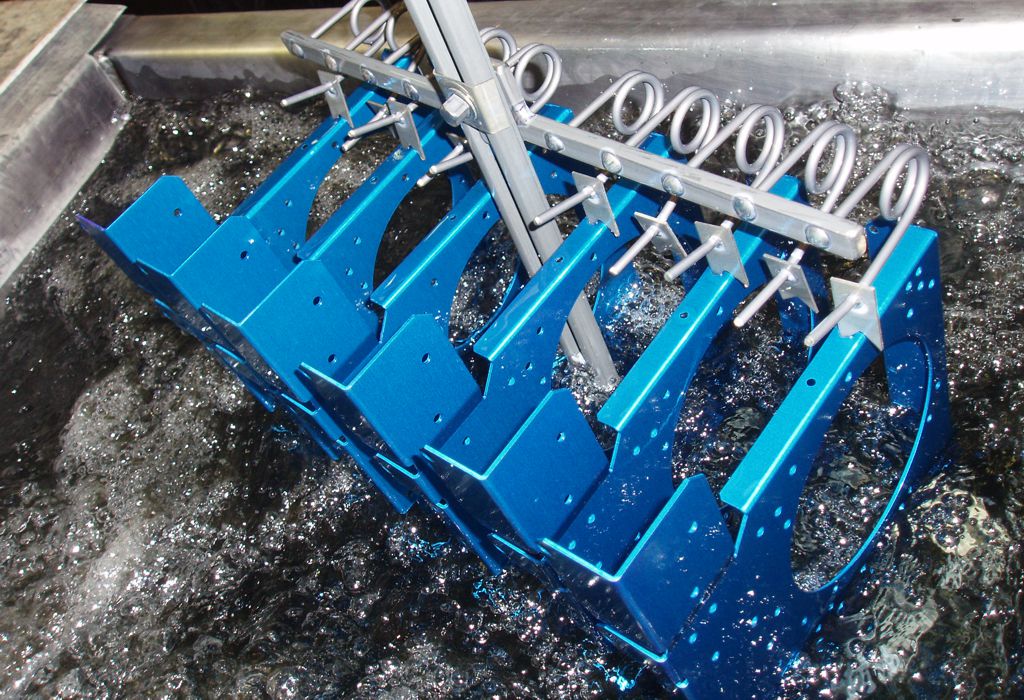

We now have a state-of-the-art Aqua Blasting facility which utilises the latest technology. Advanced process control measures allow us to maintain excellent consistency.

The key to aqua blasting is that the finish is produced through the flow of water borne abrasive, giving a finer finish due to the flushing action of the water. No media is impregnated into the component,

nor is there any dust created by the break-up of media, unlike dry blasting where the finish is produced by sheer force of media impact.

Aqua blasting provides the perfect pre-anodising finish to aluminium.

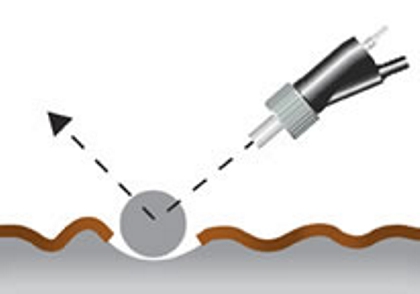

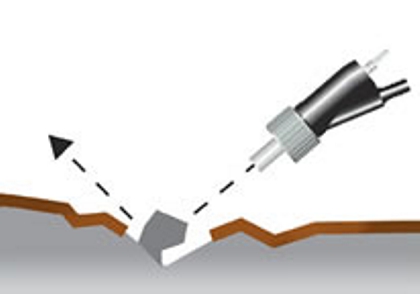

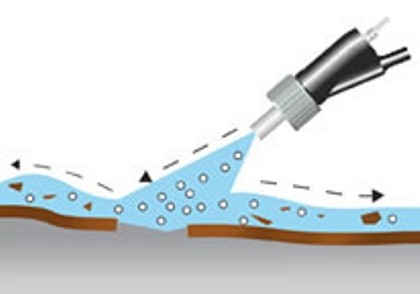

The illustrations below show the different natures of conventional grit and bead blasting compared to Aqua Blasting

Bead blasting demonstrates the aggressive abrasion caused by the severe 90° ricochet of the material fired

Dry grit blasting also exhibits severe and uneven pitting, caused again by the 90° ricochet of the inconsistent material

Aqua Blasting is a gentler method where the media angle is reduced by the cushioning effect of water to produce a lapping effect travelling across the surface, giving an even satin/polished finish

Quality is about meeting the needs and expectations of customers.

We are committed to ensure that the impact of our operation on the environment is reduced to as low a level as is practically and economically feasible

Holland Street

Greater Manchester, M26 2RH

EMAIL andrew.buckley@anodising.com

TEL +44(0) 161 723 2637

FAX +44(0) 161 725 9252

© 2022 COLOUR ANODISING LIMITED. All Rights Reserved.